金屬加工類型:選擇什麼

June 18, 2019通過成功製造產品的所有細節和決定,至關重要的不是忽視選擇適當的重要性金屬精加工方法對於部分。雖然有很多金屬精泰pes, all of them essentially involve the process of applying a layer to the surface to treat the exterior of the product. Each method provides different results in addition to a variety of benefits and disadvantages.

完成不同金屬的整理完成以達到設計的所需外觀和表麵紋理。施加治療還可以增加腐蝕和旋光的保護,增加厚度,強度,硬度和耐用性。通過提高導電性或電阻來提供較高的硫化潛力,可以在金屬精加工過程中完成許多目的。

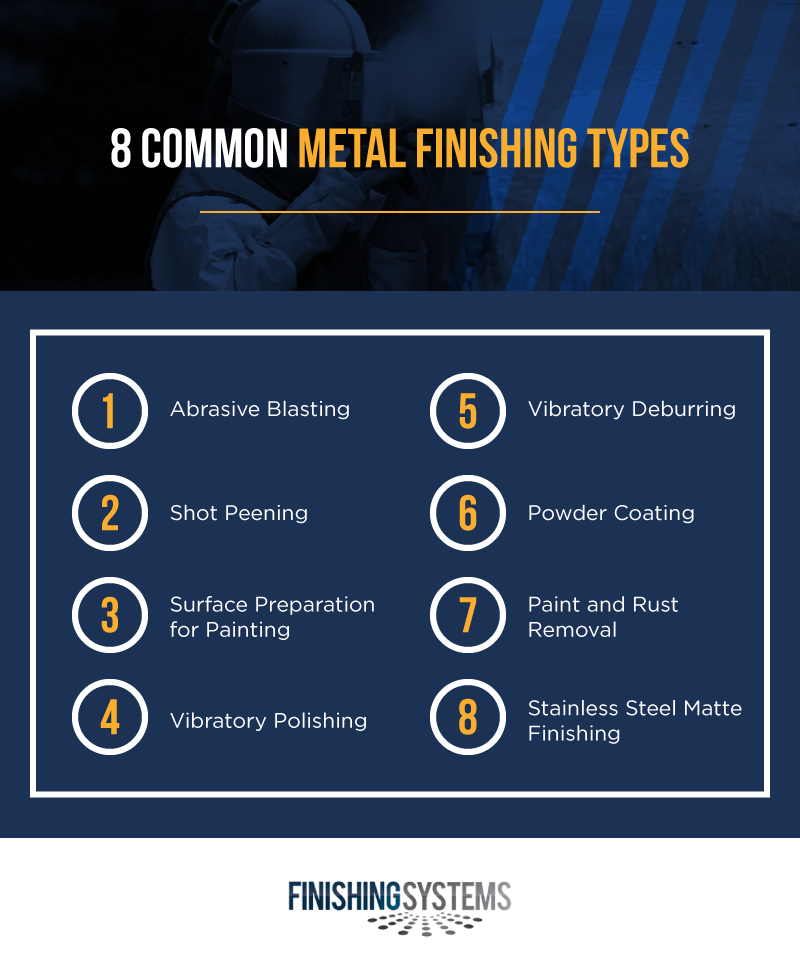

The following is a list of common finishing types for metals:

- Plating:涉及電解鈍化的過程產生陽極氧化塗層,其厚度,硬度和耐磨性和耐腐蝕性增加。

- Anodizing:涉及電解鈍化的過程產生陽極氧化塗層,其厚度,硬度和耐磨性和耐腐蝕性增加。

- Blasting:The operation of propelling grains of abrasives such as sand or beads at a metal surface in a blast to create a smooth and attractive finish.

- 繪畫:將塗層應用於金屬,主要用於表麵保護,並為美觀添加顏色。油漆是an affordable way防止惡劣環境中的腐蝕。

- 拉絲金屬:使用磨料帶或鋼絲刷以平滑表麵缺陷和略微圓形邊緣。該過程在金屬表麵上產生均勻的穀物質地。

- 熱黑色:將氧化物層施加到留下黑色的表麵上的高溫過程增加硬度,並提供耐磨損和腐蝕的卓越抗性。

- Buffing:Buff polishing utilizes a cloth wheel to remove metal from the surface for an exceptionally smooth and lustrous finish. It is often applied for its excellent ability to enhance surface aesthetics.

- Grinding:金屬研磨是應用摩擦,磨損和/或壓縮的過程,以實現硬金屬表麵的變化水平。它通常是用於實現特定公差的加工的最終步驟。

- Vibratory finishing:振動精加工機清潔,除垢,DEBURRS和鈍的鋒利邊緣,以拋光和準備高批量生產的小零件。

- 粉末塗料:Applying powder to metal electrostatically and putting it through a heated process to harden the coating for exceptional impact resistance, durability and uniformity.

- Passivation:A treatment using citric and nitric chemicals on steel to remove surface contaminants for enhanced resistance to corrosion. Passivation also helps with achieving close tolerances and retaining the dimensional integrity of parts.

Choosing Between Metal Finishing Types

Reviewing the various types of metal finishes can give you a good idea of what style is best for your project or application. Once you narrow your choices, you should consider a few other factors before making the final decision. Whether you are in a time crunch or are trying to stick to a budget, certain types of finishing may be a better option for you than others based on certain aspects.

Consider the following factors when you’re searching for the right metal finishing style:

- 生產時間:擁有生產性供應鏈對企業至關重要。當您需要一個項目或設備的金屬部件時,您可能需要遲早需要它們。一些金屬精加工比其他金屬精加工需要更長的時間。請谘詢製造商以了解您正在考慮的每種類型的金屬精加工的生產時間。維護您的供應鏈的生產力和效率是優先級,並在快速生產時間內找到合適的金屬整理過程可以是您的業務的重要選擇。

- 金屬硬度:Depending on the type of metal you’re using and its hardness, you may need to focus on certain types of finishing. Harder metals typically require a stronger and more intense finishing style so the finishing will show up on the metal. Tough techniques are best for hard metals because they are more abrasive than others that work better on soft metals.

- 整理費用:Prices range for the various metal finishing types. Before looking into these styles, evaluate the average cost for each type and select the finishing option within your budget. Like many other products, the more expensive options come with higher quality, a faster production process and more versatility. Asking the manufacturer plenty of questions about the quality of the metals and comparing prices between finishings you like can impact your purchasing decision.

這些考慮因素和其他人將幫助您找到貴公司的正確金屬整理解決方案。其他因素占您的首選精加妝,以及您正在使用的金屬的屬性,例如耐熱性和硫化的可能性。

接觸金屬整理項目OB体育APP线路的精加工係統

Searching for the right metal finishing is simple when you understand the types of finishing processes available, how to narrow down your search and what other aspects can impact your choice. If you’re interested in learning more about metal finishing types or looking for assistance with your project, get in touch with Finishing Systems. We’re a leading source for metal finishing for companies large and small across the country.